Natural Gas Overview

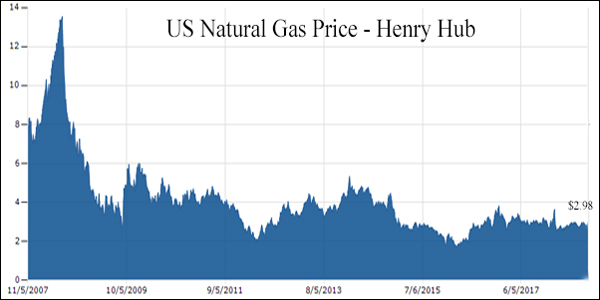

As can be seen from the graph at the left, US natural gas production peaked about the year 2000 and was in a slight decline until around 2005. Production was expected to further decline as "conventional" wells began to dry up and new ones were few and far between. Then shale gas drilling, also called "fracking", which had been experimental for some time, really took off. Natural gas production began to grow by leaps and bounds. As a result the price of nat (natural) gas dropped from a high of about $14 per thousand cubic feet (mcf) in late 2005 to $1.89 in the spring of 2012. The price has since risen to the $3.50 range in the fall of 2012.

This tremendous drop in price has transformed the energy sector. In the electricity generation market excluding nuclear power, natural gas competes with coal at most power stations. Most electric utilities have both coal and gas generators. Historically coal has been used as a "base" generator with gas used as a supplement when needed. Coal generators take a long time to fire up and down so they are used 24 hours a day as the first (base) source of electricity. Gas generators can be fired up relatively quickly and are normally used for medium and peak

requirements, but historically at higher costs. The recent low natural gas prices have caused many utilities to switch to gas as a primary fuel in locations were both types of plants are available. In the summer of 2012, the EIA (US Energy Information Association) reported that for the first time ever, natural gas fired power plants generated more electricity than coal fired plants. In just a few years time shale gas has transformed our energy economy and changed the economics of competing fuels, not only for coal and nuclear, but also renewables like solar, wind, and geothermal.

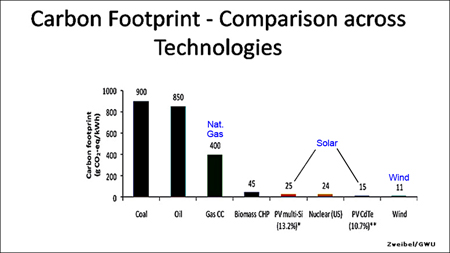

As the chart to the left shows, natural gas is not a perfect solution to the excess carbon dioxide and greenhouse gas problems. Nat gas has a carbon footprint about 44% that of coal and 47% of oil. That is no where near solar and wind which are in the 1 to 2% range. However nat gas is much cheaper than solar and wind at this point in time. Therefore many people think of natural gas a very good "interim" solution until renewables bring their costs down into a competitive range. It turns out that market forces are stronger than climate warming forces which has resulted in the US reducing its CO2 emissions faster than anyone had anticipated. See the US Emissions Are Down section. Top

Conventional Natural Gas

About 300 to 400 million years ago the land masses we live on today were just forming. The climate was warmer and ancient trees and plants grew everywhere among swamps and bogs. When these living things died, they decomposed and were buried under layers of mud, rock, and sand. Eventually thousands of feet of earth covered them. In some areas, the decomposing materials were subsequently covered by ancient seas which have since dried up and/or receded. Coal was formed from the remains of trees, ferns and other plants.

Oil and natural gas were created from organisms that lived in the seas and were buried under ocean sediments. Long after the great ancient seas vanished, bacteria, heat, and pressure combined to compress and "cook" the organic material under the layers of silt. Oil formed first, but in deeper underground regions, the hot cooking process continued until natural gas formed.

Over time, some of this oil and natural gas began working its way upward through the earth's crust until they ran into rock formations called "caprocks". See the illustration to the left for conventional gas and oil formations. Caprocks are very dense rock formations that prevent the oil and gas from seeping to the surface. Oil and natural gas were initially retrieved by drilling through caprocks. As caprock gas wells became exhausted, explorers began using a new technique called "fracking" to retrieve gas and oil buried in shale which had not been able to flow up to the caprock.

Today we can use machines called "digesters" to turn organic material (plants, animal wastes, etc.) into natural gas. This process replaces the millions of years required for the gas to form naturally. Top

What Are Shale Rock and Shale Gas?

Shale Rock. Shale is a fine grain sedimentary rock formed from compacted sand and silt (mud). Sedimentary rocks include sandstone, limestone, and shale. Shale rock is "laminated" and "fissile". Laminated means the rock has many thin layers. Fissile means that the rock easily splits into thin pieces along the laminations. Shale is a very common rock and comes in many colors - red, brown, yellow, green, gray, and black. Black shale normally indicates the presence of organic material. Just a few percent of organic materials can give the rock a dark gray or black color.

A layer of sedimentary rock begins from the weathering of rocks on land. Weathering breaks rock down into clay minerals and other small particles which become part of the soil. Over time, rain washes the tiny particles of soil from the land into streams. When streams slow down and enter an enclosed body of water, such as a very large lake, the mud particles settle to the bottom. If undisturbed, buried, and under pressure for many years, the layer of mud is eventually transformed into sedimentary rock.

Shale rock is made up of very small particles which means the spaces between particles are also very small. In fact they are so small that oil, natural gas and water have difficulty flowing through the rock. Therefore, shale layers can serve as a natural gas traps and also block the flow of underground water. Although the individual spaces in shale are very small they can make up a significant volume of the rock. This allows shale to hold large amounts of water, oil, or gas.

Shale Gas. Organic materials in black shale indicate that gas or oil are normally present. (Organic particles mean that the particles were once alive.) Organic materials from millions of years ago decayed into thick shale rock layers. If the organic material in the shale was properly preserved and heated after burial, oil and natural gas were produced. Different amounts of heat and pressures changed some of the organic material into oil and some into natural gas. See the illustration at the left showing a typical shale deposit.

Other Natural Gases. As can also be seen at the left, some natural gas has migrated out of the shale and has flowed upwards to the caprocks and some remains trapped in the shale. "Associated gas" means gas that is found with oil under caprocks, while "non-associated gas" is found by itself. "Conventional" nat gas drilling is used for non-associated gas. Originally when gas was found drilling for oil, it was burned off and wasted. Today it is collected, sold and considered a bonus find in a well.

"Tight sand gas" is sandstone bearing gas that has a very low permeability (very low flow through ability). It is difficult to recover tight sand gas because of e rock formations normally surrounding the deposit. Coalbed methane is another form of natural gas that is extracted form coal beds. "Coalbed methane" is distinct from a typical sandstone reservoir as the methane is actually stored within the coal itself.

Gas Plays. Very large underground shale formulations containing natural gas are called "plays". See the US map at the left. The green areas are areas currently producing gas from shale plays. The dark brown areas are known to have carbon shale but are not yet in production. In 1998 Mitchel Energy was the first group to use a fracturing technique to extract natural gas from the Barnett Shale Play in Texas. The Barnett Play contains enormous amounts of shale gas. The largest US play is the Marcellus Play that runs from New York State down through Pennsylvania, Ohio, West Virginia and Kentucky. Due to its abundance of shale gas reserves, the US has jumped into the top 5 countries in the world with proven natural gas reserves. Top

What Is Natural Gas Made Up Of?

| Methane | 70-90% |

| Ethane | 0-20% |

| Propane | 0-20% |

| Butane | 0-20% |

| Carbon Dioxide | 0-8% |

| Nitrogen | 0-5% |

| Hydrogen Sulfide | 0-5% |

| Oxygen | 0-.2% |

| Trace Gases | - |

Natural gas is a combustible mixture of hydrocarbon gases shown in the table at the left. In its purest form, natural gas is 100% methane. Natural gas is colorless and odorless in its pure form. However, as a precautionary measure, mercaptan (a gas with the smell of rotten eggs) is normally added to natural gas before it is delivered to end users so that it can be smelled in case of a leak.

In many wells there are considerable amounts of larger carbon compounds, namely ethane, propane, and butane, which are co-produced with methane. These are known as natural gas liquids (NGLs) not to be confused with liquid natural gas (LNG) which is natural gas that has been chilled into a liquid state (-260°F) for transportation purposes. NGLs are used in petrochemical plants, for space heaters and barbecues, and blended into gasoline. Wells that have an abundance of these extra gases are known as "rich" wells. "Lean" wells are wells that produce lots of methane gas but few NGLs.

With the recent low prices for pure natural gas (methane) most of a producer's profit comes from NGLs which have not had such a dramatic reduction in price. Producers jest that they are really drilling for NGLs and the methane natural gas comes for free. Many lean wells are being temporarily shut down until natural gas prices increase. Top

What Is Fracking?

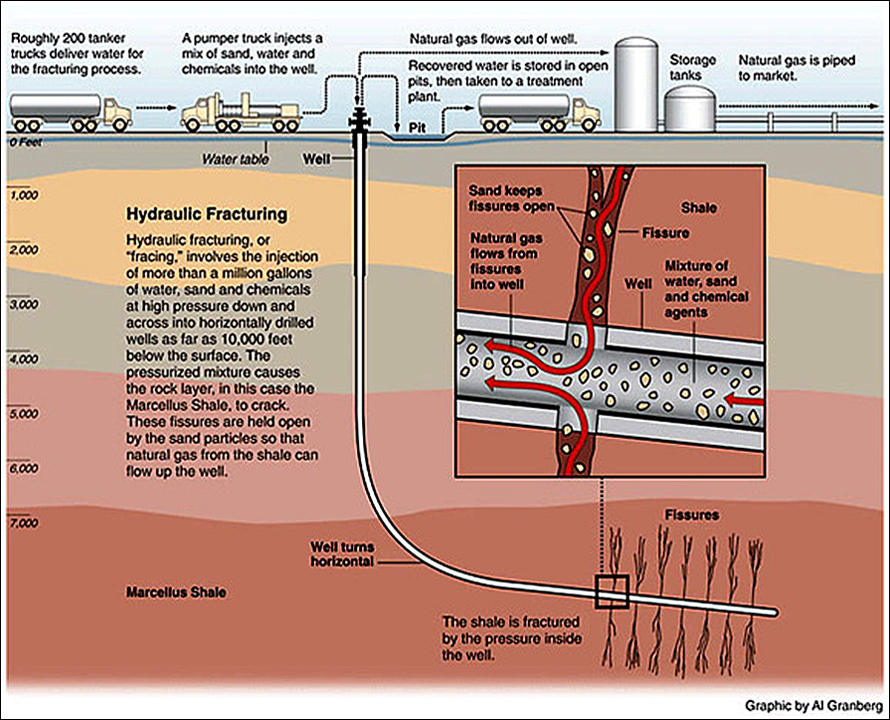

Hydraulic Fracturing (fracking for short, sometimes spelled fracing) is a drilling technique that dramatically increases the amount of gas that can be retrieved from a well. Liquids are pumped through a bore hole into deep rock formations under very high pressure. The pressures are high enough to fracture the surrounding rock freeing up the natural gas. The concept is to create a network of fractures that allow the imbedded natural gas to flow to the well bore.

Fracking combined with horizontal drilling has turned unproductive organic rich shales into some of the largest natural gas fields in the world. The Marcellus Shale and Barnett Shale plays are examples of unproductive formations that have been converted into extremely productive fields by fracking. In the case of the Barnett Play, the wells were very deep and the ground pressure was so great that the fractures closed when the pumps were turned off.

"Frac Sand" was added to the fracking fluid at Barnett to keep enough pore space open so that the natural gas could continue to flow into the well. In the picture to the left, frac sand is on the right side and a typical sand of similar grain size on the left. The frac sand has a very uniform grain size, rounded grain shapes and a uniform composition. Frac sand is also a very tough material that is highly resistant to fracturing. It is a highly specialized, crush resistant material produced primarily for use by the gas and oil industry.

Frac sand is normally a natural material made from high purity sandstone. An alternative product is ceramic beads made from sintered bauxite. Frac sand is known as a "proppant" because it props the fractures open. The characteristics of a high quality frac sand include: high-purity silica sand, grain size matched to the job requirements, a spherical shape that enables it to be carried in the hydraulic fluid with minimal turbulence, and durability to resist the crushing forces of closing fractures. Over one million pounds of sand can be used while fracking a single well. Adding frac sand to a fracture mixture is now standard practice. For more information about fracking and horizontal drilling see Geology.com. Top

Horizontal Drilling

Horizontal wells start off as a vertical wells. Vertical drilling continues until the drill bit is a few hundred feet above the target rock layer. At this point a hydraulic motor is attached to the drill. The hydraulic motor is powered by the flow of drilling mud down the drill pipe. It can rotate the drill bit regardless of the original orientation. This allows the bit to drill a path that is different from the vertical drill pipe.

The hydraulic bit drills a path that takes the well bore from vertical to horizontal (or other angle) over a distance of a few hundred feet. Once the well has been adjusted to the new angle, drilling resumes and the well follows the target rock formation. Keeping the drill in a thin rock layer requires careful navigation. In-the-hole instruments are used to steer the drill through the shale layer. The "departure" from the vertical of a drill in a shale formation can go several miles in the new direction versus only about 50 feet in a pure vertical well. And, it can go several miles in all directions covering a circular area within a several mile radius. (The departure record as of 2011 for horizontal drilling is 40,000 feet. See Longer Deviated Wells.)

Horizontal drilling is expensive. When combined with hydraulic fracturing, a well can cost about twice as much per foot as drilling a vertical well. The extra cost is usually recovered by the increased gas production from the well. Fracking and horizontal drilling in a given well multiply the yield of natural gas by about 4 times versus conventional drilling while the cost increase is about 2 to 1. The United States has been a leader in developing these technologies and exploiting them for market share. Top

Shale Gas Operations

Water is the main fluid used in the hydraulic fracturing process. Depending upon the well and the rock being fractured a few million gallons of water can be required for a fracking operation. As the water pressure builds up in the well, fractures open in the rock, and the high pressure extends the fractures deep into the rock formation.

Chemicals are added to the water used in fracking. Some thicken the water into a gel that is more effective at opening fractures and carrying the frac sand deep into the rock formation. Other chemicals are added to reduce friction, keep rock debris suspended in the liquid, prevent corrosion of equipment, kill bacteria, and control the acidity of the water. Sand is the most commonly used frac material but aluminum beads, ceramic beads, and other materials have also been used. Top

US Natural Gas Prices

The quoted price of natural gas is normally the spot price for 10 billion British Thermal Units (10,000 mmBtu) of energy delivered at the Henry Hub. (10 billion Btu is approximately equal to a million cubic feet (mcf) of natural gas and sometimes the gas price is quoted in mcf instead of Btu.) The Henry Hub is a distribution hub on the natural gas pipeline system in Erath, Louisiana which connects to 16 other pipelines. "Physical prices" at other delivery location are based on the Henry Hub price plus the "basis" increment for the other location.

When an aging coal power plant has to be upgraded because of environmental regulations, it is much cheaper and more environmentally friendly to replace the coal plant with a natural gas plant. Virtually all old coal plants are being dismantled and no new ones are planned. In 1985 coal plants produced 57% of the US's energy needs, by 2017 that percentage had dropped to only 14%.

Natural gas demand usually peaks during the coldest months of the year (December - February) and is lowest during the "shoulder" months (May - June and September - October). During the warmest summer months (July - August), demand increases again. Due to the shift in population in the United States toward the sun belt, summer demand for natural gas is rising faster than winter demand. The export market probably has the biggest long term upside potential for natural gas. Gas prices in Europe and Asia are three (Europe) to four (Japan) times higher than in the US.

Top